Loading...

Our Advantages

Engineering is in our blood. Whilst working with you to meet your budgets and timescales, you can trust that we will never cut corners or compromise on material quality. If we make it for you, it will be right.

Common Components

Display Systems, Lightning Conductors, Food & Catering, Transport & Automotive, Railways, Shopfitting & Display, (And Many Others).

Optimised for speed

Investment in machines and equipment over the years has meant that capacity has increased and our lead times are protected.

Everything Engineering

CNC Punch, CNC Sheet Bender, Tube Bending, Mig, Tig and Spot Welding, Drilling, Cutting, Milling & Lathe Work, Press Work, Wire Work.

Highly customizable

We manufacture our own pressing equipment and other tooling in our well equipped tool room.

Machinery

From small brackets to larger and more complex fabrications, we can produce your metal product with quick turn around and competitive pricing.

CNC Punching

Producing parts in thicknesses up to 4mm, with a maximum sheet size of 1250mm.

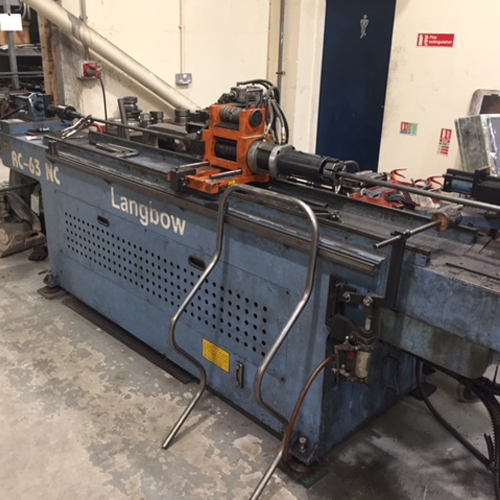

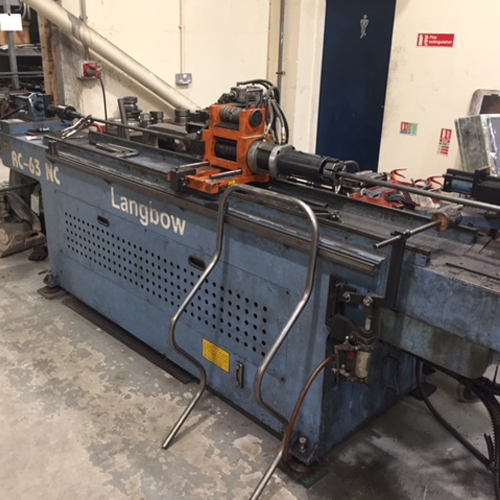

CNC Tube Bending

Handling multiple bends in a range of popular sizes.

MIG & TIG Welding

Welding in Mild Steel, Stainless and Aluminium.

CNC Bending

Folding parts up to 3M long, press brakes with an extensive range of tooling.

Metal Pressing

Multiple power presses operating under 60 tons for precision stamping

In House Tooling

We manufacture our own press and other tooling in our well equipped tool room.